Any deviations from this exercise really should be evaluated to be sure there are no detrimental consequences on the material's Physical fitness for use. Wherever achievable, food stuff grade lubricants and oils need to be made use of.

A statement of the load or measure of sample employed for Each and every exam as described by the strategy; data on or cross-reference on the preparation and tests of reference expectations, reagents and standard options

Generation and laboratory Manage information of noncritical approach measures may be reviewed by capable generation personnel or other models subsequent processes accepted by the quality device(s).

Rejected materials needs to be recognized and controlled beneath a quarantine method intended to avert their unauthorized use in manufacturing.

There should be a created and accredited deal or official settlement among a company and its contractors that defines in detail the GMP responsibilities, including the quality actions, of each celebration.

Single Use Assist focuses on the event of answers to the production of active pharmaceutical ingredients employing solitary-use engineering. The maintenance of closed techniques and automation of procedures are designed to copyright the very best good quality benchmarks in output, efficiently eliminating human mistake and reducing products decline.

Published methods ought to be recognized and adopted with the overview and acceptance of batch manufacturing and laboratory control records, which include packaging and labeling, to determine compliance with the intermediate or API with established specifications just before a batch is launched or distributed.

Personnel really should wear clean apparel well suited for the manufacturing action with which They can be included which garments need to be improved, when acceptable.

Out-of-specification batches shouldn't be blended with other batches for the goal of meeting specs.

The circulation of materials and personnel from the setting up or facilities must be meant to reduce blend-ups or contamination.

Future validation should normally be done for all API processes as defined in twelve.1. Prospective validation of the API course of action need to be completed ahead of the professional distribution of the final drug item manufactured from that API.

Crucial: Describes a method phase, course of action ailment, test requirement, or other appropriate parameter or merchandise that must be managed in just predetermined conditions in order that the API meets its specification.

Info on the name of your intermediate or API which include, the place acceptable, its grade, the batch range, as well as the day of launch needs click here to be provided around the certification of study.

Gear calibrations need to be done working with specifications traceable to certified benchmarks, when they exist.

Scott Baio Then & Now!

Scott Baio Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Nancy Kerrigan Then & Now!

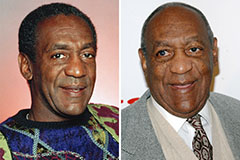

Nancy Kerrigan Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!